Common Challenges in Structural Steel Detailing Services and How to Overcome Them - SILICON VALLEY INFOMEDIA PVT. LTD.

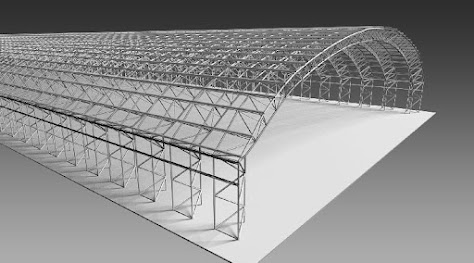

Structural steel detailing services are critical in the construction industry as they help bring the vision of architects and engineers to life. They play a vital role in the manufacturing process of steel structures, which are then used in buildings, bridges, and other large-scale infrastructure projects. However, like any other industry, some challenges arise during the process of providing steel detailing fabrication drawings services. In this blog post of Silicon Valley Infomedia Pvt. Ltd., we will explore some of these challenges and offer tips on how to overcome them.

Challenge #1: Miscommunication

One of the most significant challenges in the steel detailing fabrication drawings services is miscommunication. This can occur at any stage of the process, from the initial design to the final construction phase. Miscommunication can cause delays, mistakes, and even safety issues. To overcome this challenge, it is important to establish clear communication channels and protocols. Ensure that everyone involved in the project understands their roles and responsibilities and that communication is open and transparent.

Challenge #2: Complex Designs

Structural Steel Detailing Services often deal with complex designs that require a high level of accuracy and precision. Steel structure fabrication drawing services require a thorough understanding of design principles and engineering concepts to ensure that the final product meets the required standards. To overcome this challenge, it is essential to hire experienced and skilled steel detailing professionals who have the knowledge and expertise to handle complex designs.

Challenge #3: Time Constraints

Another common challenge faced by the steel detailing fabrication drawings services is time constraints. Steel fabrication shop drawings services require meticulous attention to detail, and any delays can cause a ripple effect on the overall construction timeline. To overcome this challenge, it is essential to establish a clear timeline and ensure that all stakeholders involved in the project are aware of the deadlines. This can help streamline the process and ensure that the project is completed on time.

Challenge #4: Cost Management

Structural Steel Detailing Services can be expensive, and cost management is a significant challenge. The cost of steel detailing services can vary depending on the complexity of the project, the skill level of the professionals involved, and the timeline. To overcome this challenge, it is essential to establish a budget upfront and work with steel detailing professionals who are transparent about their pricing. It is also important to ensure that the project is managed efficiently to avoid any unnecessary costs.

Challenge #5: Quality Control

Quality control is a critical aspect of steel detailing fabrication drawings services. Structural Steel Detailing Services require a high level of precision and accuracy to ensure that the final product meets the required standards. To overcome this challenge, it is essential to establish a quality control process that includes regular checks and balances throughout the project. This can help identify any issues early on and ensure that the final product meets the required standards.

Challenge #6: Adapting to New Technologies

Technology is rapidly advancing, and steel detailing professionals need to adapt to new tools and software to remain competitive in the industry. Steel detailing fabrication drawing services require a high level of technical expertise, and it is essential to stay up-to-date with the latest tools and techniques. To overcome this challenge, it is important to invest in training and development to ensure that steel detailing professionals have the skills and knowledge required to work with new technologies.

Structural Steel Detailing Services are essential in the construction industry, and like any other industry, they face challenges. Miscommunication, complex designs, time constraints, cost management, quality control, and adapting to new technologies are some of the common challenges faced by the steel detailing fabrication drawings services. However, with proper planning, communication, and collaboration, these challenges can be overcome. By working with experienced and skilled steel detailing professionals who have the knowledge and expertise to handle complex designs, you can ensure that your project is completed on time, within budget, and to the highest standards.

Additionally, it is important to establish a culture of collaboration and open communication between all stakeholders involved in the project. This can help to prevent miscommunication and ensure that everyone is working towards the same goals. Regular meetings, updates, and progress reports can help to keep everyone on the same page and ensure that any issues are addressed promptly.

Another way to overcome the challenges of Structural Steel Detailing Services is to establish clear standards and guidelines for the project. This can help to ensure that everyone is working towards the same goals and that the final product meets the required standards. Standards can include things like project timelines, quality control processes, and design principles.

In addition to clear standards and guidelines, it is also important to have a robust quality control process in place. This can help to identify any issues early on and ensure that the final product meets the required standards. Quality control can include things like regular checks and balances, reviews of the design and fabrication processes, and inspections of the final product.

Finally, it is important to invest in training and development for steel detailing professionals. New technologies and tools are constantly emerging in the industry, and steel detailing professionals must have the skills and knowledge required to work with these new tools. Training and development can include things like workshops, seminars, and online courses.

many challenges can arise during the process of providing steel detailing fabrication drawings services. Miscommunication, complex designs, time constraints, cost management, quality control, and adapting to new technologies are just some of the common challenges that steel detailing professionals face. However, by establishing clear communication channels and protocols, setting clear standards and guidelines, having a robust quality control process in place, and investing in training and development for Structural Steel Detailing Services professionals, these challenges can be overcome. With the right team and the right approach, steel detailing fabrication drawings services can help to bring the vision of architects and engineers to life and ensure the successful completion of construction projects. As steel detailing plays a crucial role in the success of any construction project, it is essential to have a comprehensive understanding of the common challenges faced in the industry and how to overcome them.

One of the key challenges in providing Structural Steel Detailing Services is dealing with complex designs. As the complexity of the design increases, so does the difficulty of creating accurate fabrication drawings. Steel detailing professionals need to have a deep understanding of the design and the ability to translate that into detailed fabrication drawings. To overcome this challenge, it is important to have a team of experienced professionals who can work collaboratively and use their expertise to ensure that the final product meets the required standards.

Another challenge in the steel detailing industry is time management. In many cases, there are strict deadlines that need to be met to keep the construction project on track. Steel detailing professionals need to be able to work efficiently and effectively to ensure that the project is completed on time. One way to overcome this challenge is to use advanced software tools and technologies that can help streamline the steel detailing process and reduce the amount of time required for manual processes.

Cost management is another challenge that needs to be addressed in Structural Steel Detailing Services. As the cost of raw materials and labor continues to rise, it is essential to find ways to minimize costs without compromising on quality. This can be achieved through careful planning, accurate estimates, and effective cost-management strategies.

In addition to cost management, quality control is another important factor that needs to be considered in steel detailing fabrication drawings services. Any errors or mistakes in the fabrication drawings can result in costly delays and rework. Quality control processes such as inspections, reviews, and testing can help to ensure that the final product meets the required standards.

Finally, adapting to new technologies is another challenge that steel detailing professionals need to overcome. As the industry evolves and new technologies emerge, it is important to stay up-to-date with the latest tools and techniques. This can include using 3D modeling software, virtual reality technology, and other advanced tools to improve accuracy and efficiency in the steel detailing process.

Overall, providing Steel Detailing Fabrication Drawings Services, Steel Structure Fabrication Drawing Services, and Steel Fabrication Shop Drawings Services can be challenging, but with the right approach, these challenges can be overcome. By prioritizing communication, setting clear standards, having a robust quality control process, investing in training and development, and staying up-to-date with the latest technologies, steel detailing professionals can deliver accurate and high-quality fabrication drawings that meet the needs of architects, engineers, and construction professionals.

Comments

Post a Comment