The Role of BIM in Precast Panel Detailing Services.

What is Precast Panel Detailing?

Precast Panel Detailing is like making super-detailed Design documents for big pieces of concrete used in the structure. These pieces are made in a plant and then put together at the building site.

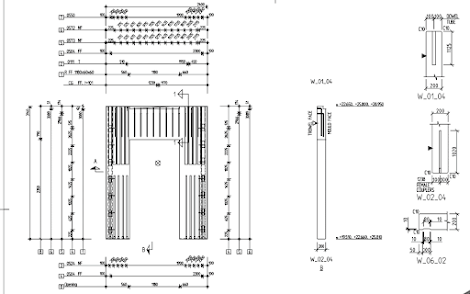

The detailing process involves creating very precise drawings and teachings. These plans tell the factory exactly how big the pieces should be, what kind of concrete to use, where to put the metal inside them, and other important details.

Why is this important? If these plans aren't perfect, they can cause problems during building. The pieces might not fit together correctly, or they might not be strong enough, which can slow down the construction and make it less safe.

So, precast panel detailing is all about making sure everything is just right before the building starts. It's like having a super-detailed recipe to bake a perfect cake, but in this case, it's about building structures with big concrete pieces.

What is BIM?

Building Information Modeling (BIM) is like using an outstanding computer to help build things. Instead of just drawing pictures, BIM makes a 3D model that has lots of useful information about what's being built. This includes stuff like what materials to use, how much it'll cost, when different parts should be done, and how well everything will work when it's finished.

BIM is not just a computer program, though. It's a really helpful tool that lets architects, engineers, and builders work together easily. It's like a guide that helps them plan, build, and manage a building project from start to finish.

BIM is like having an assistant for CAD projects, making them easier, more organized, and efficient. It's like having a detailed plan that surrounds everything from start to finish.

The Role of BIM in Precast Panel Detailing:

Building Information Modeling (BIM) is a smart way to prepare and assemble things like houses and buildings. It's like creating a digital copy of a building on a computer. This helps architects, builders, and maintenance people work together better. BIM is super helpful in making sure that things like precast panels (big concrete pieces) are made accurately and well. So, BIM is really important in the precast panel industry.

Silicon Valley Infomedia Pvt. Ltd. furnishes a service where they make explicit drawings for precast panels. These drawings show how big the panels are, what they're made of, where the reinforcement goes, and where they should be placed. These drawings are really important because they help people make the panels correctly and put them in the right place. If there are mistakes in these drawings, it can cause big problems like delays, extra costs, and even safety issues in the structure work.

BIM (Building Information Modeling) has completely transformed how we design and build precast panels. It's like a powerful computer program that helps designers, engineers, and builders work together smoothly. With BIM, we can make very detailed 3D models of precast panels and use them to create exact drawings for making the panels. Using BIM has made these drawings much more accurate, which means we make better-quality precast panels and build items faster.

Certainly! Building Information Modeling (BIM) software is like a set of digital tools that are used in the design and planning of precast panels, which are large concrete pieces used in structures. These tools have several benefits:

BIM software allows designers to create precast panel designs that can be manufactured using different methods, such as casting them in place on the construction site, making them in a factory (precast), or tilting them up into position. So, it's flexible and can be adapted to various building techniques.

Designers can use BIM Services software to analyze the detailed drawings of the precast panels. This analysis isn't just about making sure the design looks good; it also checks if it's easy to build, good for the environment, and cost-effective. In other words, BIM helps designers make sure that the panels are not only visually appealing but also practical and efficient.

BIM software is a digital tool that helps designers create precast panels that can be built in different ways and ensures these panels are not only well-designed but also easy to build and cost-effective. It's like having a smart computer assistant for designing edifice elements.

BIM software makes it easy for designers, engineers, and builders to work together in real-time when planning precast panels. It's like having a virtual meeting where everyone can talk and share ideas instantly. This helps them find and fix problems quickly, so the project doesn't get delayed or cost more.

BIM software also makes the process of making precast panels better. It creates very detailed drawings that show exactly how the panels should be made. This helps the team making the panels understand what's needed and make them correctly. So, there are fewer mistakes, and the panels match the design and quality standards, making the whole process smoother.

BIM software also helps the team that works on precast panels create very precise and detailed instructions for putting them in place. These instructions show the builders exactly how to install the panels. This makes it less likely for mistakes to happen during installation, which keeps everyone safe.

These specific instructions also make the installation process faster and cheaper because everyone knows exactly what to do. So, BIM software makes sure the panels are put in the right way and saves time and money.

Using BIM for making plans (drawings) for precast panels has made these panels more eco-friendly and long-lasting. BIM software lets designers check if the panels are good for the environment and if they'll last a long time. It also helps them design the panels to be energy-efficient and not cost too much over their lifetime.

The accurate plans made with BIM also make sure the panels are built and put in the right way, so they work well and don't break early. This means the panels are better for the environment and stay in good shape for a long time.

BIM is like a legend in the world of designing precast panels. It has made everything way better.

Here's how:

- Accuracy: BIM software makes sure the plans and drawings are exactly right.

- Efficiency: It makes things happen faster and smoother.

- Quality: The final product (the precast panels) is better and lasts longer.

BIM has also:

- Reduced Mistakes: Less room for errors in the planning.

- Improved Teamwork: People work together better.

- Helped the Environment: It makes sure the panels are good for the planet.

- Made Building Easier: The whole construction process works better.

Also, BIM software helps the teams that make plans for precast panels to work together with other teams and their computer systems, like those for electrical, plumbing, building structure, and construction management. This teamwork makes sure that the precast panels are designed and put in place properly, so there are fewer chances of delays and safety problems.

Additionally, BIM software can do something really helpful: it can look at data and tell us how well the project is going. These facts help the team see where they can do better, make the structure process work even smoother, and use data to make smart choices that make the whole project go well.

We are highlighting the growing significance of using Building Information Modeling (BIM) in the construction industry in the United States. Here's what it means:

Importance of BIM in the USA Construction Industry:

BIM is becoming increasingly important in the field of designing precast panels in the United States. The CAD industry in the USA is highly competitive and moves at a fast pace.

Competitive Advantage:

When construction companies adopt BIM for precast panel design, it gives them a competitive edge. They can do several things better:

- Cost Reduction: They can save money.

- Quality Improvement: Their work becomes of higher quality.

- Efficiency Increase: They can complete projects faster.

Improving Profitability and Competitiveness:

All these advantages ultimately lead to construction companies making more money and being better than their competitors in the market.

In simpler terms, using BIM for designing precast panels is a big deal in the fast-paced and competitive building industry in the USA. It helps companies save money, do better work, and finish projects more quickly, which means they can make more profit and outperform their rivals.

To sum it up, BIM is super important for making plans for precast panels in construction. It's like a digital teamwork tool that helps designers, engineers, and builders work together smoothly and do a great job. BIM makes sure everything is accurate, works well, and is top quality. So, it's not just good for the environment and the wallet; it also makes sure the final product is really good and lasts a long time.

Check out our latest reaserch on the - REVIT Architecture Engineering Services

Comments

Post a Comment