The Advantages of 3D Rebar shop Drawings in Construction Design

What is 3D Rebar Modeling?

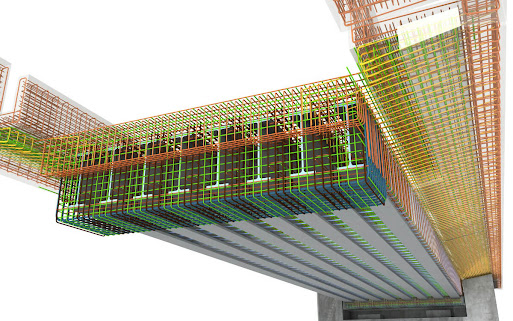

3D Rebar Modeling is an advanced method and practice in the construction industry. It includes generating a precise, three-dimensional computer model of reinforcement bars, often known as rebar. Rebar is an essential component of many concrete structures because it adds strength and stability.

Engineers, architects, and construction professionals can use this modeling method to create a virtual, 3D blueprint of how rebar is positioned within a concrete structure. It's similar to producing a computerized map that shows exactly where each piece of steel rebar should be positioned to ensure the building or structure fulfills the appropriate strength and safety criteria.

Construction experts can plan and arrange the installation of these steel bars with precision by visualizing the rebar layout in 3D space. This level of detail and accuracy is extremely advantageous since it reduces errors and guarantees that the building is both safe and robust. It also increases building efficiency since workers may utilize the 3D model as a guide, lowering the risk of errors and redo.

In essence, 3D rebar modeling is a high-tech tool that allows construction experts to build a three-dimensional digital representation of rebar installation within concrete structures. This facilitates correct planning and design, resulting in more efficient and error-free construction procedures and, ultimately, ensuring the structural integrity and safety of the completed structure or project.

Following are tthe advantages of 3D Rebar Modelling.

The Evolution of Rebar in Construction

For decades, reinforcing steel, or rebar, has been an essential component of architecture. It gives structures strength and durability. Traditional rebar detailing services and drawings, while effective, had limitations.

I. Improved Architectural Quality

Precision Matters: How 3D Modeling Elevates Accuracy

In the drive for precision, 3D Rebar Modelling has emerged as an industry mover. Unlike 2D drawings, 3D models show the whole arrangement of the rebar, guaranteeing that every element fits correctly. This precision decreases the possibility of mistakes during construction.

Error Correction in Traditional Rebar Design

Traditional rebar detailing was frequently based on manual interpretation, which left the possibility of human error. In contrast, 3D Rebar Modelling allows for precise calculations and minimizes misconceptions, resulting in fewer mistakes during production.

II. Improvements in Interaction and Communications

Bridging the Gap: Architects, Engineers, and Contractors

Collaboration among engineers, architects, and models is vital for the success of a project. 3D models serve as the universal language that connects these parties. They can more clearly visualize and discuss the design.

The Universal Standard of 3D Models

3D Rebar Modelling simplifies complicated topics and allows for cross-discipline collaboration. This amicable collaboration speeds up decision-making and keeps everyone on the same page, avoiding delays and misconceptions.

III. Time and Cost Efficiency

Time is Money: The Swiftness of 3D Rebar Modeling

3D Rebar Modelling is defined by its ability to save time. It speeds up the design process and allows for real-time adjustments and updates. This speed saves construction companies time and money in the long run.

Saving Resources and Reducing Waste

Because 3D models are more accurate, fewer on-site modifications are required, resulting in less material waste and more efficient resource utilization. This benefits not only the project's financial line but also the environment.

IV. Safety First

Ensuring Safety through Comprehensive Rebar Models

In the structure industry, safety is of the utmost importance. 3D Rebar Modelling aids in the creation of thorough safety plans, assisting in the identification of potential dangers and the reduction of risks during the construction process.

Averting Construction Accidents and Mishaps

The accuracy of 3D models minimizes the possibility of structural flaws causing accidents. It provides a sharper image of the structure, protecting worker safety and building integrity.

V. Sustainable Construction

3D Rebar Modeling and the Green Building Revolution

Sustainability is no longer an option; it is a need. 3D Rebar Modelling plays an important part in this transformation by decreasing waste and supporting ecological building principles.

Reducing Environmental Impact, One Model at a Time

A lower environmental footprint means less trash. 3D Rebar Modelling aids green building by assisting builders in making optimal use of materials and reducing their environmental impact.

VI. Complex Shapes Made Simple

Conquering Architectural Challenges with 3D Models

Complex, non-standard structures are common in modern architecture. 3D Rebar Modelling succeeds in meeting these obstacles, bringing even the most elaborate designs to life with precision.

Beyond Rectangles: Rebar in Non-Standard Structures

3D Rebar Modelling can suit the different needs of architects and engineers, from curvilinear forms to irregular geometry, making previously inconceivable concepts a reality.

VII. Precise Material Estimates

The Secret to Efficient Resource Management

Accurate material estimations are critical for budget management. 3D Rebar Modelling guarantees that the correct quantity of materials is ordered, avoiding overruns and underestimations.

Eliminating Overruns and Underestimations

Avoiding material shortages or over-ordering can save engineering firms a lot of money and assist in shortening project schedules.

VIII. Future-Proofing Designs

Adapting to Change: 3D Rebar Modeling for Renovations

Buildings frequently necessitate renovations or alterations. 3D models make it easier to respond to these changes, saving time and resources.

Preparing for the Unforeseen in Construction

In a sector where unexpected obstacles are typical, 3D Rebar Modelling gives designers the flexibility to react to changing project needs and unexpected events.

IX. Quality Control

Building Right the First Time

To meet and surpass industry requirements, quality control is essential. 3D Rebar Modelling decreases the margin for mistakes and aids in creating high-quality structures.

Meeting and Exceeding Industry Standards

3D Rebar Modelling is a significant resource for ensuring uniformity and quality across building projects while conforming to industry standards and codes.

X. Visualizing the Final Product

Bridging the Gap from Design to Reality

Before the building begins, stakeholders may see the finished product in 3D. This instills trust and excitement among clients and investors.

Inspiring Stakeholders with 3D Renderings

Detailed 3D renderings and visualizations provide a clear preview of the final product, instilling confidence and enthusiasm for the project's success.

XI. Regulatory Compliance

Navigating the Regulatory Landscape

Various building norms and regulations must be followed during building phases. 3D Rebar Modelling aids compliance by verifying that designs satisfy these specifications.

Ensuring Adherence to Building Codes

Builders can reduce costly revisions and setbacks due to non-compliance by adding regulatory criteria into the modeling process.

XII. Risk Management

Mitigating Risks through Comprehensive Rebar Models

Risk management is an essential component of architecture. 3D Rebar Modelling aids in the identification and mitigation of possible dangers before they become costly issues.

Protecting Your Investment and Reputation

A proactive approach to risk management protects the project's integrity and a company's reputation, resulting in improved long-term performance.

XIII. Enhancing Project Documentation

Detailed Records for Seamless Project Management

Detailed project documentation is required for efficient project management as well as future maintenance or repairs.

Facilitating Maintenance and Repairs

Detailed 3D models serve as a helpful reference for continuous maintenance and repairs, ensuring that necessary work is completed as quickly as possible.

XIV. Streamlined Estimations

Simplifying the Bidding and Quoting Process

Winning deals for building services frequently rely on the accuracy of estimates. 3D Rebar Modelling simplifies the bidding and quoting process, improving the likelihood of project success.

Winning Contracts with Accurate Estimates

Developers may give competitive bids with precise estimates, enhancing their chances of obtaining deals and growing their operations.

XV. Innovations in Rebar Materials

Modern Materials for Modern Construction

The building business, like the materials utilized in it, is always evolving. 3D Rebar Modelling can work in tandem with advanced rebar materials to promote design.

The Synergy of 3D Models and Cutting-Edge Rebar

Incorporating new materials into 3D models improves the efficiency, durability, and sustainability of buildings.

XVI. Case Studies

Real-World Examples of 3D Rebar Modeling Success

Real-world success stories are essential for understanding the full impact of 3D Rebar Modelling. Several projects have benefited from the use of this technology.

Learning from Projects That Excelled

The examination of these case studies provides insights into the practical benefits of 3D Rebar Modelling and how it may be used in various types of construction initiatives.

XVII. Overcoming Challenges

Addressing Concerns and Hurdles in Adoption

While the benefits of 3D Rebar Modelling are great, their implementation can be difficult. Recognizing and addressing these concerns is critical to a successful shift.

Strategies for a Smooth Transition

Effective training and open communication are critical techniques for overcoming resistance to change and successfully integrating 3D Rebar Modelling into manufacturing processes.

XVIII. Training and Education

Empowering the Industry with 3D Rebar Modeling Skills

As its building industry embraces 3D Rebar Modelling, education and training are critical to preparing the workforce for the future.

Preparing the Workforce for the Future

Investing in training programs ensures that industry personnel is prepared to realize the full potential of 3D Rebar Modelling.

XIX. Looking Ahead

The Future of Construction: 3D Rebar Modeling on the Horizon

The construction business is on a fast track. Looking ahead, we can investigate the prospective advances and breakthroughs that will define the future of construction design.

Conclusion

3D Rebar Modelling, by embracing the paradigm shift in construction design, holds enormous power in transforming our reality. With its multiple benefits, it is apparent that this technology is revolutionizing the way we build, promising the construction industry a brighter, more efficient, and greener future. We can expect safer, more accurate, and ecologically sensitive construction practices as 3D Rebar Modelling becomes the new norm, making our built environment a better place for all.

Comments

Post a Comment