What Is The Role Of MEP Coordinator In Construction?

Coordinating mechanical, electrical and plumbing(MEP) systems is a tough job for large-scale building projects like industries. It accounts for almost 40 percent of a building’s construction budget. MEP coordination is time-consuming and it requires expert guidance on each system for entire project lifecycle. Current practice in construction project requires MEP coordinator to bring sound perspective for making decisions among the project teams.

Why are MEP coordinators required?

• Owners do not have full knowledge pertaining to the engineering part of the MEP systems and thus they require a second opinion from MEP coordinator to take right decisions.

• Construction contractors require MEP coordinators to resolve any problems early during the initial stage of the project cycle rather than at the end. It is also costly to make changes after everything is purchased and installed on the site. Hence, MEP coordinators must be involved in the project early to carry out MEP Co-ordination when everything is on the paper itself.

• Another important role of MEP coordinator is to challenge the cost estimates provided by subcontractors.

• Owners do not have full knowledge pertaining to the engineering part of the MEP systems and thus they require a second opinion from MEP coordinator to take right decisions.

• Construction contractors require MEP coordinators to resolve any problems early during the initial stage of the project cycle rather than at the end. It is also costly to make changes after everything is purchased and installed on the site. Hence, MEP coordinators must be involved in the project early to carry out MEP Co-ordination when everything is on the paper itself.

• Another important role of MEP coordinator is to challenge the cost estimates provided by subcontractors.

What does the MEP system coordinator do?

• Based on the complexity and need of the project, MEP coordinator gets involved during several stages of the lifecycle.

• Basically, they are involved early during preconstruction stage so that the owners can take more accurate decisions for bidding and construction.

• They assist with the mechanical, electrical and engineering designs. They deal with the construction issues, from preconstruction through construction.

• A coordinator provides a more reformed perspective, unlike designers and contractors, to verify the engineering decisions.

• Their goal is to make sure that the engineering designs meet the owner’s requirements including scope, budget, quality, maintenance, performance and more.

• During the construction phase, they help to track the quality of installation and resolving field issues.

• Based on the complexity and need of the project, MEP coordinator gets involved during several stages of the lifecycle.

• Basically, they are involved early during preconstruction stage so that the owners can take more accurate decisions for bidding and construction.

• They assist with the mechanical, electrical and engineering designs. They deal with the construction issues, from preconstruction through construction.

• A coordinator provides a more reformed perspective, unlike designers and contractors, to verify the engineering decisions.

• Their goal is to make sure that the engineering designs meet the owner’s requirements including scope, budget, quality, maintenance, performance and more.

• During the construction phase, they help to track the quality of installation and resolving field issues.

What kind of experience is required by MEP coordinators?

MEP coordinators require design experience, subcontractor experience, and maintenance experience. MEP contractor is required to have an understanding of several areas including technical, management and budgeting. The most important qualification required by them is a strong engineering design background.

Conclusion:

The overall role of MEP coordinator is to support different team members of the project related to MEP systems. They need someone else who can bridge the gap for them to make sure their buildings are completed in a manner that successfully meets the needs of the occupants and is not a burden to operate over the life cycle.

We are offering MEP Co-ordination services:

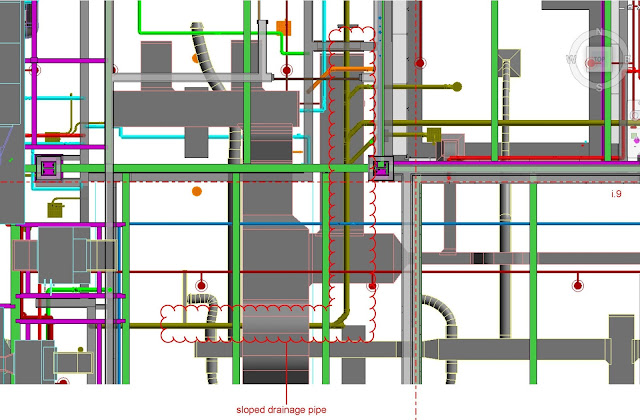

Effective MEP coordination requires integrating knowledge regarding design, construction, operations, and maintenance of each MEP system. Currently, designers and constructors use CAD technology to design and fabricate MEP systems. Silicon Valley Infomedia Pvt Ltd is a reputed company offering MEP designs using CAD for MEP Coordination Drawings and MEP Coordination Shop Drawings.

We provide BIM Coordination Modeling service so as to aid MEP contractors, owners, designers, and other team members for an effective outcome. We also provide MEP Coordination Outsourcing Service. For more details on the services provided by us, please visit our website.

Feel free to contact us with any query you have regarding our services. Our consultants will provide appropriate guidance for your queries.

Comments

Post a Comment