Benefits and Advantages to Sheet Metal Fabricators while moving from 2D Drafting Services to 3D Modelling

The current market, as well as the business trend, has advanced to a great extent. With the use of the latest software, technique, and practice of international standards, the work for sheet metal fabricators, manufacturers, and contractors has indeed become very quicker, easier, and faster. Now when in structural engineering services, the work of sheet metal fabrication and sheet metal drawings play an important role.

The post today which is being shared by Silicon Valley is focussing on the core advantages and benefits for sheet metal fabricators when they tend to move ahead from traditional 2D drafting services to creating 3D sheet metal models.

It is a fact that in today’s 21st century too there are metal fabrication businesses that are still believing in working with the same age-old concept of 2D drawings, even after when we know that technology has advanced and there is an option of Sheet Metal 3D modeling available in the market. The entire process of sheet metal design services tends to have an important place and with that, it has a certain level of technical packages that need to be used for other departments like quality and marketing utilize drawings to develop different publications.

The use of 2D drawings or 2D geometry still seems to be prevalent, but the fact is that it is time-consuming and because of it the level of productivity is impacted to a great extent and at a great level of significance. Moreover, if considering the same aspect and level of work, the team of fabricators and manufacturer will come across with the drawback and this will therefore lead to an inability of the drawings which will therefore not maintain any type of collaboration between the parties who are responsible to get the update of the design intent clearly and precisely.

Not only this, one of the biggest drawbacks yet occurs in using the concept of 2D drawings and designs are the cause of miscommunication and production scrap. This issue is very much familiar with the team of steel fabricators, but yet with knowing this fact, the team still undergoes the same concept of 2D processes. Well, considering all these aspects, what facts and figures can be predicted is the steel fabricator having fear of losing their business or due to having less experience for the said resources.

Thus, to avoid such discrepancies and get the result as per the expectations of the clients, the modern work and era demand newness. This is only possible with the help of adopting the new form of services and that is none other than migrating the work from 2D drafting to Sheet Metal 3D Modeling.

Moving further, below is the list mentioned that discloses some of the benefits of advantages that closely relate to the idea concept of outsourcing Sheet Metal Design Services to the company that has years of experience and is well-versed with the latest tools and technology of the current market trend and demand.

Benefits/Advantages

1. Improved Design and Drawings

The foremost and the direct benefit is entirely being depicted in its design level. It is that if the level of design is accurate and precise the chances here get increased for qualitative work and less amount of wastage or scrap. Also, with the use of international standards and codes the team of sheet metal fabricators can easily work on the design and drawings parts of the project.

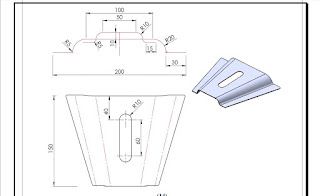

Not only this, software like SOLIDWORKS which is considered a 3D CAD modeling tool has indeed taken the level of sheet metal design services to its peak where the demand to get 100% success is more as that compared to 2D modeling services. Also, with the use of its key factors entire sheet metal can be prepared with required marking and sectioning.

2. Qualitative Approach and Drafting Accuracy:

Every company or team of contractors or sub-contractors will demand the level of work that is having quality and with that accuracy. In simple terms, the services should be clash-free and error-free. With the use of the latest software and tools, the engineers will be able to deliver work that is qualitative and has much accuracy. This is all possible with the help of international standards, the latest techniques, and tools.

3. Complete Market Engagement Materials:

The process of the work is always two ways. The team of is sheet metal fabricators will only be able to design sheet metal when the client will share their idea, concept, and along with that the shop drawings for the said work. With the help of these sets of inputs and communication between the two, the entire work becomes materialistic and engages with the duo.

4. R&D of Design Virtually

Once the entire sheet metal design is been prepared by the team of sheet metal fabricators, it is necessary that thorough R&D for the same is to be done. This again is only possible with the help of a cloud-based server that gives access to the designs and drawings virtually to the client irrespective they are residing in whichever part of the country.

5. Automating the process:

To make the work easier and faster the best thing is to automate the process. Once the work is being done the data must be stored in the server and whatever changes either party does, the same can be viewed and implemented at the same time. Thus automating the process is ideally a great concept to be getting work done.

Conclusion:

Silicon Valley is the leading sheet metal design services provider offering services to its clients globally. With 13+ years, of experience, we have become the first choice for clients and sheet metal fabricators when they think to migrate their work from the traditional 2D methods to 3D sheet metal modeling services.

To know more about the working method or to outsource your project, you can speak to the team at Silicon Valley along with the process of getting free quotes as well.

For more details:

Web:

Email: info@siliconinfo.com

Comments

Post a Comment